Advantages of expanded metal mesh

Fils expanded metal mesh offers many advantages: strength, look and eco-compatibility. New applications and solutions are constantly being added to the long list of existing uses of expanded mesh thanks to our experts' input.

Recyclable and sustainable

Fils expanded metal mesh respects the environment. No pollutants are used in our production processes and the expansion process generates no waste. At the end of its long working life, expanded mesh can easily be disposed of and is 100% recyclable.

Strong and durable

Expanded metal mesh is a robust metal material. In terms of its mechanical strength, it can support even very heavy loads with the proper fixings and reinforcement. Perfect for solid safety and protection barriers. Also suitable for fencing and parapets.

The appropriate finishes (e.g. varnishing, galvanising or anodising) prolong the life of the mesh.

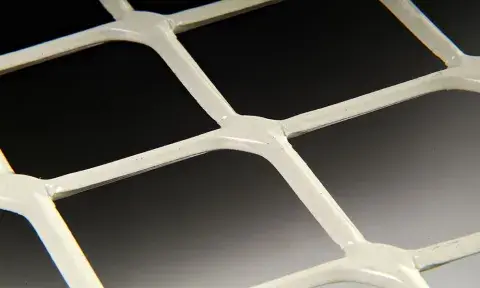

Configurable and workable

By choosing the right thickness and solid/elastic structure, we can tool and "transform" expanded metal mesh by cutting, welding, folding or curving it, without any risk of permanent deformation or breakage.

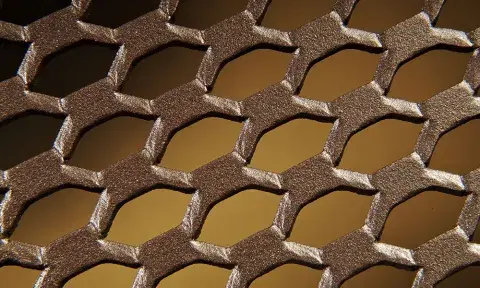

Non-slip expanded metal mesh

Fils grating is great at preventing accidents: the mesh is non-slip, high-heel safe and stops panic. Fils 21 mesh has been awarded the highest score (R13) foreseen by the strict German norm DIN 51130. Find out more.

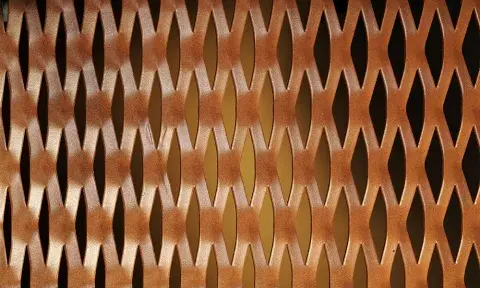

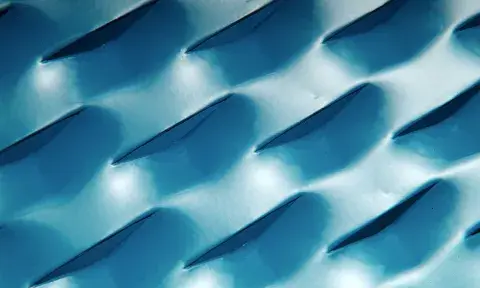

Transparent to light and air

The apertures in the expanded mesh let in light, create aesthetic effects and allow for communication on either side. In schools, offices and workplaces in general, daylight makes for comfort and higher productivity. The open shape of expanded metal mesh also makes it suited to applications that require ventilation and the free passage of air, such as in parking facilities, utility rooms or transit areas.

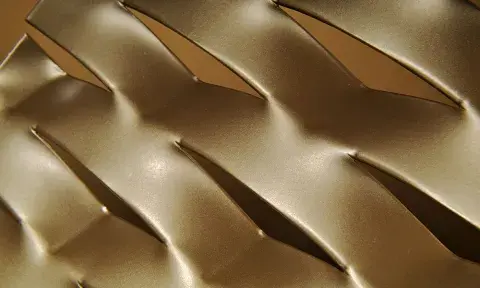

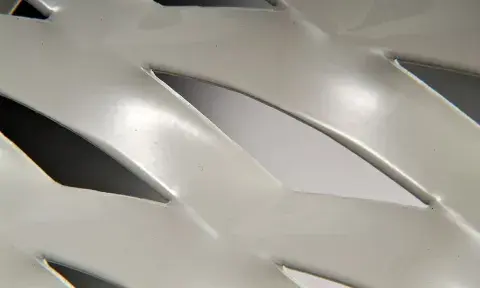

Shading

Expanded metal mesh is a unique material that is both transparent and yet capable of providing shade all at the same time thanks to its particular three-dimensional conformation. This characteristic makes it ideal for innovative shading solutions for the regulation of sunlight: the shade provided is greatest when the sun is at its highest, while the frontal opening of the mesh maximizes the amount of daylight and leaves the view open to the world outside. This makes rooms brighter and cooler at the same time.

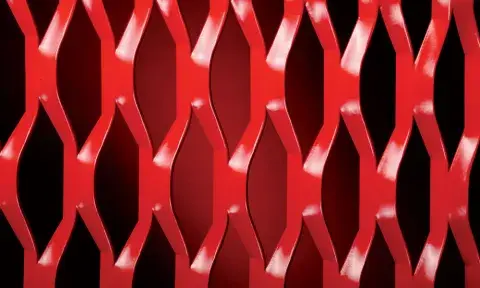

The look

Expanded metal mesh is much appreciated by architects and is ideal for high class out-fitting thanks to its harmonious geometry and suitability for wide, well-lit spans. Technical areas, such as utility rooms and ecological stations, often need to be separated by barriers. Expanded mesh is perfect for this, and pleasing to look at. Once again, expanded mesh is a practical, low-cost solution.

.

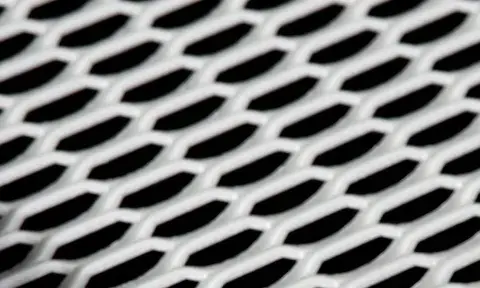

Privacy

In urban settings you can create corners protected from sight by using expanded metal mesh, such as Ambasciata, which allow you to see out, but prevents others from looking in. "Calibrated" degrees of masking can be used to get the amount of privacy you want. Mesh can also be used as dividers, in offices or industrial work areas, for instance.

The versatility of expanded metal mesh

Being easy to work with and the wide choice of shapes means expanded metal mesh can be adapted to suit the application and easily combined with other materials, such as glass, wrought iron or natural stone.

Innovative

New products made from expanded metal mesh are being added all the time, meeting even the most complex needs of users, architects and designers working in a variety of sectors. Customers are able to work in close co-operation with our Technical Office. This, plus the flexibility of our production departments (all in-house), mean we can carry out tests and produce prototypes to ensure we meet your needs.

Low cost

The fact that no waste is produced when making expanded mesh means that this is a cheaper solution than punched sheet metal. The intrinsic structure of the mesh - being a single piece - makes it lightweight, but at the same time stronger than other materials of the same weight.