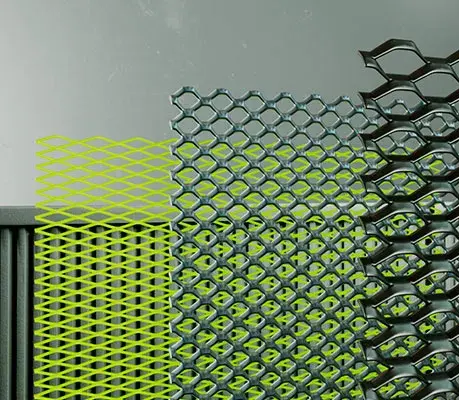

In the following sections you will find all the information on the wide range of expanded metal (also called metal mesh). The ability to select the mesh geometry, material and thickness will help you choose the expanded metal mesh that best suits your needs. For architectural applications see the section Architecture meshes. If you need ‘heavy-duty’ expanded metal, see the Gratings section.

Expanded metal

The applications of expanded metal

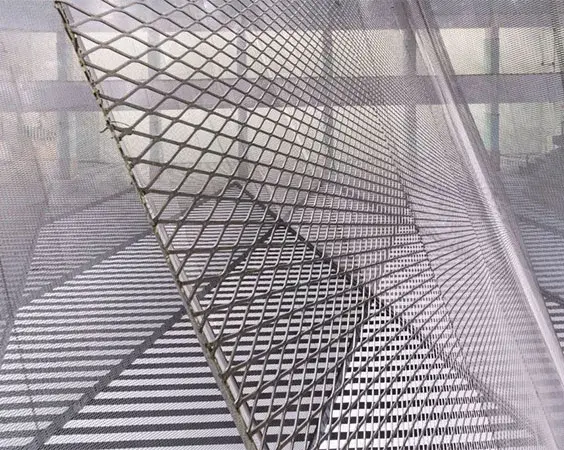

Why are expanded metal sheets used in so many industrial and architectural applications?

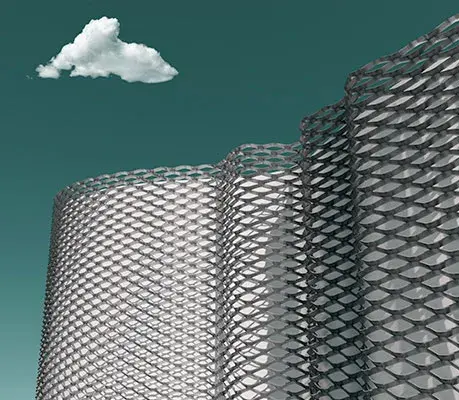

The reason for this versatility lies in the numerous processing possibilities of this material. Here are some of the processes that can be performed to obtain the finished products required in the various sectors of use.

- Cutting to length

- Folding and pleating

- Flattening

- Bending and waving

- Edging with profiles

- Painting, hot-dip galvanising and anodising

Discover all the advantages of expanded metal!

Contact our experts for dedicated support in choosing the right products for your project and cost optimisation.

Choosing the right mesh

By listening to your needs we can help you choose the most suitable expanded metal mesh by evaluating the different options available:

- the geometry of the mesh: square, diamond, hexagonal

- the module: from a few millimeters up to 800 mm with Ultra Limited meshes

- transparency: from very closed mesh to very open mesh

- shading

- ventilation

In the article on transparency, you can learn more about the functional aspects related to the opening of the expanded metal mesh, which regulate the aspects of passage of air, light and heat. This functionality is relevant for both industrial and architectural sectors.

Don't forget the choice of protective finish. Contact us.

See resources

FAQ

Expanded metal can be produced using various materials that can be 'stretched' thanks to their mechanical characteristics.

The most commonly used materials in the construction industry are undoubtedly carbon steel and Sendzimir carbon steel. Aluminium is used for cladding applications in architecture. Expanded metal sheets can also be made from various types of stainless steel (e.g. AISI 304, AISI 316 and others) for applications that require specific resistance properties in high temperature environments or corrosive atmospheres.

Expanded metal and perforated metal are both 'open' materials. Expanded metal is produced using a 'slitting and stretching' process without wasting any of the raw material; perforated sheet metal, on the other hand, is obtained by a 'punching' process resulting in metal scrap. Another difference between these materials is the thickness: expanded metal has a three-dimensional shape that also adds to its strength. Perforated sheet metal is flat, with a constant thickness. Expanded metal can be used instead of perforated metal for many applications.

Yes. There are filters in each product section that let you choose the materials, thickness, sizes, open areas, etc. For example, in the section dedicated to our Protech Line, you can select any of these characteristics as filters to quickly get a list of products that best meet your requirements.